Phone:0411-87918678

Tel:13998428656

E-mail:fluidscare@163.com

Add:No.27 Shizi Street Dalian Industrial Park China

Product introduction

Gas scrubbing tower is used in soluble (hydrophilia) gas, liquid particles, solid particles and stinky gas incurred during the production process.

Gas scrubbing tower uses the principle of physical absorption and chemical absorption to solute hydrophilia toxic gas in water. So solubility of objects to be absorbed in water is one of the key factors for valid absorption. Physical absorption usually adopts pure water and chemical absorption and removes toxic substances in wasted gas via chemical effect. Following types of waste gas, acid or alkaline liquid are respectively used and either oxidizing agent or reducing agent is used to formulate corresponding chemical cleanout fluid to neutralize with toxic substances in waste gas into neutral salt and to guard against reverse gasification.

For example, when caustic alkali solution is used to clean sulfuretted hydrogen, sodium sulphide, sodium hydride and other chemical substances would be incurred before producing hydrogen sulfide via mutual interaction. To prevent occurrence of this case, oxidante (such as hydrogen peroxide) should be added to the cleanout fluid.

Product specification

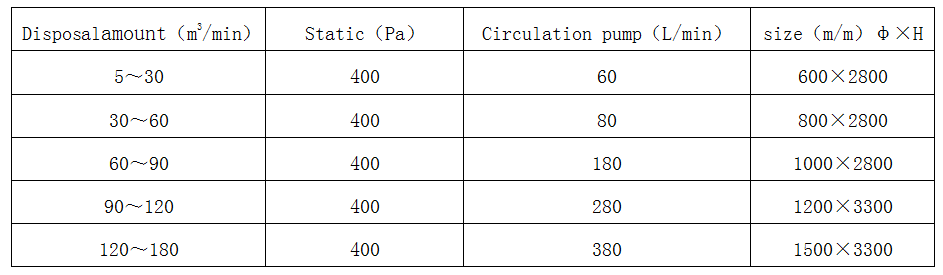

Gas scrubber specifications:

Structure

1. Reverse padding absorption system;

2. Shower system;

3. De-fogging device system;

4. Feed-water box, feed-water pump system;

5. Air inlet/ air outlet, draught fan, air hose and absorption cover.

Characteristics of the equipment

Equipment characteristics

1. Stable in performance and strong adaptability to changes of air capacity;

2. Not prone to be blogged and long continuous operating time;

3. Can be used to handle with dust gases prone to exposed and catch fire;

4. Handy in designing, proneness for management, conservation of operation fees.

Scope of application

1. Ventilation disposal, pickling bath, plating tank, drying tank and copper sulfate recovery tank in the e-industry workshop;

2. Waste gas disposal in ventilation board in libraries of hospitals and schools;

3. Waste gas disposal during work process of plating tank, pickling bath and flume tank in steel and electroplating industry;

4. Disposal of acid and alkaline gas in chemical industry;

5. Forging, model casting and flume discharge disposal of mechanical workshops;

6. Smoke disposal removed in metal smelting.