Phone:0411-87918678

Tel:13998428656

E-mail:fluidscare@163.com

Add:No.27 Shizi Street Dalian Industrial Park China

Product introduction

Drum fine screen is a kind of continuous operation, removal of suspended solids in water equipment, realize the efficient separation of solid and liquid.Can be widely used in municipal water supply, sewage system, industrial wastewater, food processing industry, paper industry wastewater treatment system.

Raw water flows through the grille, larger than the hole of suspended solids in the drum surface segregation, after being drum into the discharge area.Suspended solids contact with scraper, blown away.Filtered water at the bottom of the drum, so can eliminate the rest of the impurity on the drum, drum cleaning.Can install according to the need in the internal high pressure washing system, used to thoroughly clean the drum.

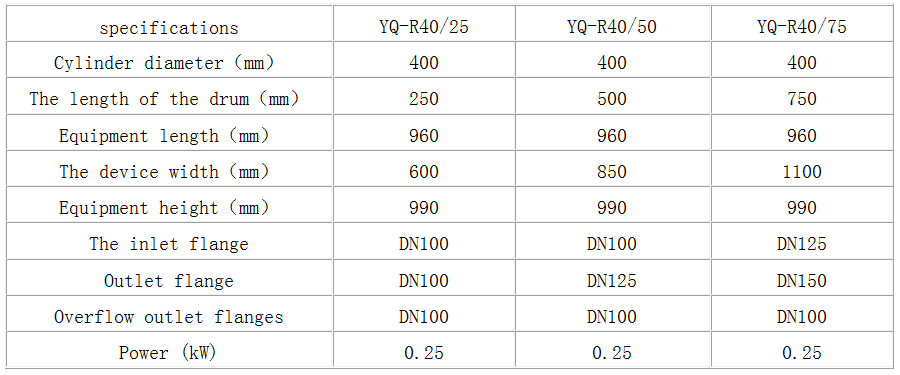

Product specification

structure

1. Drive;

2. Drum;

3. With the interior of the nozzle cleaning system;

4. The scraper blade external cleaning system;

5. Safety cover and splash guard.

Characteristics of the equipment

1. Stainless steel, corrosion resistance;

2. The drum design;

3. The filter has big filter area,

4. The filtering effect is higher than other grating;

5. In the process of running without power consumption;

6. A single processing water 1 ~ 160 m after/h;

7. Mesh opening rate is large, clearance from 0.3 mm to 3.0 mm;

When the sieve spacing increases, the water processing relative increase;

8. Good filtering effect, can significantly reduce the concentration of pollutants in wastewater, reduce the waste water treatment cost;

9. Not easy to block, can be made into fixed or turning two ways;

10. Clean and simple, the use of hydraulic cleaning or brush cleaning;

11. The equipment service life can be up to more than 10 years;

12. The installation is simple, low cost of installation.

Scope of application

1. Municipal water supply wastewater treatment system

2. Sewage system wastewater treatment system

3. Wastewater treatment system for food processing industry

4. Papermaking wastewater treatment system.

5. Industrial wastewater treatment systems.