Phone:0411-87918678

Tel:13998428656

E-mail:fluidscare@163.com

Add:No.27 Shizi Street Dalian Industrial Park China

Product introduction

Efficient degreaser has adopted a series of corrugation plate tilt closely placed according to the relative point of view, this is the most effective way to increase the contact area per unit volume of, so, it needs will be far less space than ordinary separation tank, the device can be made into pressure container for water treatment process.

Sewage by feed line into coalescence, the larger solid and sludge in coalescence parts separated from the wastewater reached the bottom of the container, the last in clean sewage exit is expelled.

Then the steady flow sewage through perforation plate, the flow is steady, after separation of the hydrophilic knit panel.

Oil bead in the plate oil rises to the top of the corrugation inclined plate combined with other small oil droplets, big oil droplets through the plate to oil-water separation interface.Coalescence of oil will flow through the central oil weir, finally from the oil discharge outlet.

Lighter solids and the separation of sludge in the plate finish at the same time, their precipitation to the bottom of the coalescence material, and then are released into the sludge ditch.

Through plate out of the water to the upper fixed water weir overflow collection, and then through the outlet pipe flow, in-depth treatment or disposal.Can be seen that efficient degreaser is a kind of three-phase separator, he not only put the lighter oil beads separated off from the water, but also dropped the heavy sediment separation, remove the mesophase - clean water.

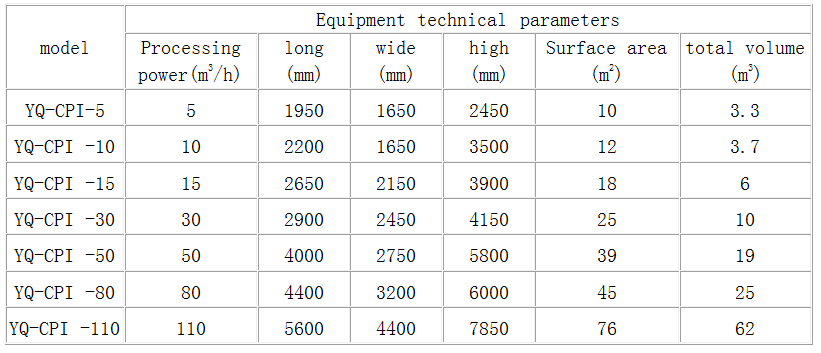

Product specification

structure

1. The water area

2. The separation zone

3. Skimming oil

4. The sludge bucket

5. Out of the water

6. Stainless steel, concrete production

Characteristics of the equipment

1. Save space;

2. High removal rate of oil and solid;

3. Low maintenance operation;

4. The seal plate height, avoid particles blocked drain tank.

Scope of application

1. The land and sea oil field wastewater treatment;

2. Oil refining and petrochemical wastewater treatment;

3. The ship, GangTou dock, oil depot tank of oily wastewater treatment;

4. Other industrial oily wastewater treatment;

5. Mechanical processing industry;

6. Metallurgical industry.